The Dawes Kingpin Shopping Bike

Supposing that you were to walk into a Household Waste Recycling Centre and see the bike pictured in the advert below, that would be a happy day. Even happier if there was a hinge in the main beam to allow folding. There are one or two features that elevate the Dawes Kingpin above the more common Raleigh Twenties that are still a good find, well worth having.

Firstly, Dawes are, or were, a maker of high-quality racing and touring bicycles, the most famous of which is the Dawes Galaxy. Galaxies are a little like Land Rovers; most of them are still on the road. Because of this heritage, Dawes really knew what they were doing when they designed the Kingpin. It is made from slender lightweight tubing and beautifully bronze-welded with loving care and plenty of bronze. All the joints are strong, including the hinge. This feature is not some cumbersome carbuncle but a neat, small design, working in exactly the same way as the current Brompton hinge. Brompton designer Andrew Ritchie copied it. Probably.

Firstly, Dawes are, or were, a maker of high-quality racing and touring bicycles, the most famous of which is the Dawes Galaxy. Galaxies are a little like Land Rovers; most of them are still on the road. Because of this heritage, Dawes really knew what they were doing when they designed the Kingpin. It is made from slender lightweight tubing and beautifully bronze-welded with loving care and plenty of bronze. All the joints are strong, including the hinge. This feature is not some cumbersome carbuncle but a neat, small design, working in exactly the same way as the current Brompton hinge. Brompton designer Andrew Ritchie copied it. Probably.

Furthermore, the brake and gear cables are routed through the frame tube and fold nicely when the bike is folded. Stainless steel mudguards remained shining forever. (Try and find a good pair of Moulton chrome mudguards now). Brakes were Weinmann alloys and the stand alloy too. It is clear that Dawes intended the Kingpin to be a serious all-round machine and they were quite weight conscious. The chrome was top quality and the lovely stem and bars purpose designed. Cranks are steel but slender and fluted.

I discovered the bike in the photo gallery below at Shipston-on-Stour Waste Recycling Centre and bought it for £5. This seems to be their standard price and really, they are very happy to sell them. I could have had a similar Raleigh Twenty too but well, one at a time. With a bit of luck, someone else would have taken that one on. My Kingpin has good paint in a contemporary metallic green, not unlike my dad's old 1969 Ford Cortina. It all came apart with no trouble at all.

The Rigida rims are a little too rusty for the rest of the bike so will be scrapped off. However, when I examined them against a new set I discovered that they were smaller. The Kingpin's tyres are 500A, which is smaller than the ETRTO metric size of 451 that you can buy everywhere. "451" refers to the diameter of the tyre bead seat in millimetres. This tyre size is also given the old-fashioned designation of 20 x 1 3/8". 20" in this case is supposed to refer to the outer diameter of the tyre. but hold on, my Kingpin's wheel are smaller than a 451 wheel and when I measured the tyre outer diameter it was 21". This quoted size of 20" is clearly just a nominal value. If you are confused, don't worry. Bicycle tyre sizes are a tangled web; everyone is confused. Find out the ETRTO size and stick to it, ignoring all other markings.

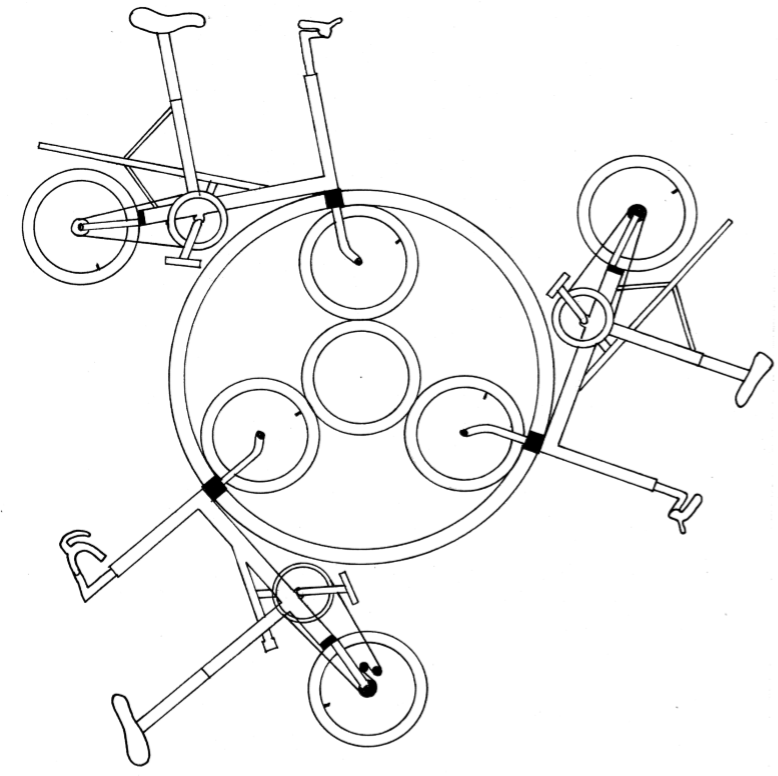

Click on first picture to start the slideshow.

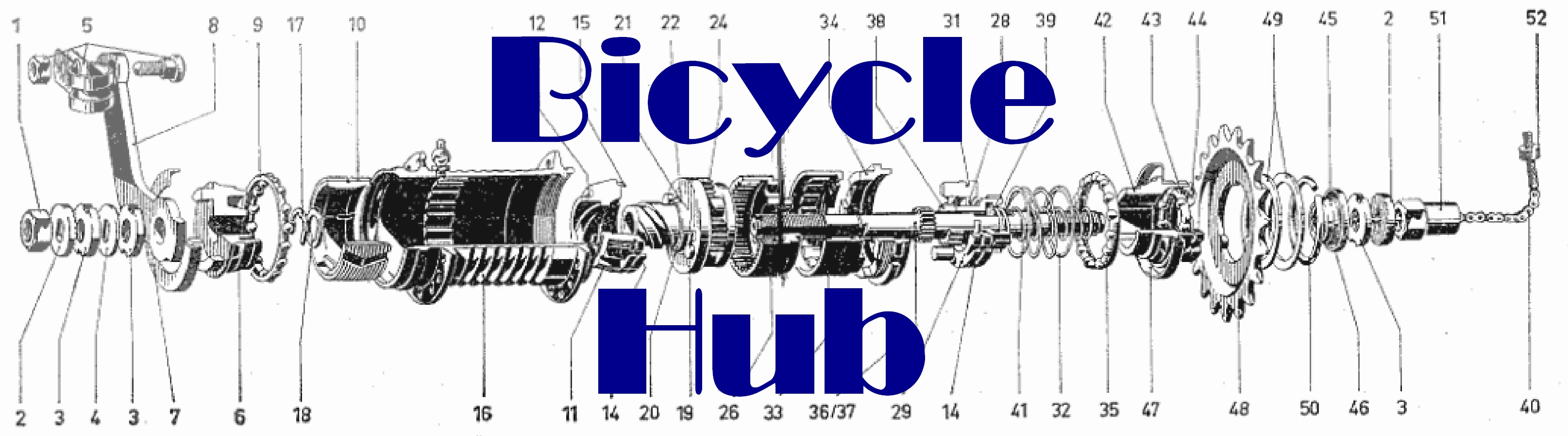

My intention is to polish everything up, build new wheels with a five speed Sturmey Archer Sprinter at the back and fit new cables and a new saddle. The Dawes saddle has their name on but I don't like old saddles.

After a rummage through my stock of bicycle parts I discovered a new 500A front wheel with a quick release hub. As the rear wheel was not too bad, a decision was made to use the unusual 500A size. Gleaming whitewall tyres are available on ebaY. I gave the spokes in the back wheel a tweak and took the hub apart for a cleaning. Lucky too, as it had a complete absence of oil. Sturmey sent some of their hubs out unlubricated, I read somewhere, to be oiled by the cycle shops. Apparently, the seller of my Kingpin forgot this necessary tribology.

After a long think about the paintwork, I decided that this should be improved. For one thing, the lettering was coming off, and when I tried to remove it all it took some paint off too. From parts that had been covered with tape I found the colour was more of a gold originally, and the pale green was a faded out hue. Finally I didn't like the warning sticker that the shop had put on it, or their crackled label. Again, the finish came off with the label. Now, powder coating is ideal, but it is not cheap. It would have been around £80 - £90 to have the frame painted in this way and I felt that I might do a reasonable job with spray paint, of which I had plenty. So, the bike was rubbed a little to remove the top layer of paint and sprayed over with a darker green. This is actually a Kingpin colour in any case.

The folowing photo sequence shows the painting process. I started by giving the paint a light rub-down, washed it with hot water and detergent, then I dried the frame with a hot-air gun. By spraying over the bare metal with a rust-inhibiting primer, we can fill in imperfections, as well as protecting against tin-worm. Be warned that paint particles do end up on all the surfaces around your spraying area. These can be wiped up as a dry coloured dust, but you can save yourself a job by doing it outside. I used some old cellulose paint that spluttered a little as it was probably down on pressure. These are no longer sold with cellulose now being a health and safety no-no, but you will be able to get acrylic spraypaint that works as well. Halfords are good for paint, although pricey.

With the spraying done and a clear laquer over the top I turned my attention to all the components. This is a familiar process that you will go through on every bicycle restoration. Good quality chrome parts chosen by Dawes are very durable. Even when it initially looks quite rusted, the item can often be cleaned up and polished with Solvol Autosol, a paste polish. Look at the chain wheel in the above photo sequence for instance; it returned to a mirror finish. Also, the beautiful Dawes designed Kingpin stem was as good as new after polishing. Chrome is actually what is termed a "galvanic" coating. That is, when you scratch the plating through to the steel, if the scratch gets wet a little battery is formed between the dissimilar metals. This causes the surrounding chrome to electroplate over the scratch and seal it. This is why chrome parts resist rust so well. Good old Eastleigh College.

If the chrome has hard speckles I tend to shave them off with a sharp knife. If the rust is in more of a film I use a brass wire brush suitable for suede. Usually a combination of these techniques is successful. Finish by polishing with the Autosol. You can protect chromework from rust with a very light coat of Vaseline. Never try to get rust off with a steel wire brush or glass paper, unless the finish of the chrome is too far gone. A steel brush will make the surface look like a skating rink. Sometimes if I find a part that has really rusted up in one place, I will remove the rust with emery cloth or wet-and-dry, then apply some grease. On Moulton stems for instance, rust often gets through the chrome under the extension when the top of the stem is still perfect. The chrome plating was perhaps a little thinner underneath. Aluminium alloy also comes up well with Solvol.

The last photo sequence shows the rebuild of the Kingpin. You will see that there are comparatively few parts and none of the operations were at all difficult. Compared with rebuilding a Moulton for instance, it was an absolute piece of pie. The only item I wanted to replace was the saddle for a more modern one. Saddles have come a long way since the sixties. I did not get as far as refitting the cables, due to having none in the stores. EbaY is the place for bulk orders of cables. Setting up brakes will be one of the subjects of a whole page of specialized tasks. The intention here is to show the general process that you will use on all older bicycles. The paint and rebuild only took me a couple of days, and I tend to work at a snail's pace.

Click on the photo to see the finished bike full-screen. Somewhere I think that I have a rear pannier rack to suit it. Dawes made really nice bags for the Kingpin with their name on the side and I will try to obtain one of these.