| Here's a K Type with a chrome finish. The K came in a choice of black (paint), nickel or chrome shells. It had the first "ribbon" logo stamped on the shell. A metal oil cap should be fitted but this one has gone walkies. |

|

| This is the hub that will be pulled apart and rebuilt. The finish looks like spray, and I'm guessing that it was on a bike that was resprayed black all over without removing the wheels! The ball ring and sprocket are painted.Could have been done in wartime. |

|

| So far, so AW Procedure. Mike has removed the cones from both sides. Note that the spring emerged from the left hand side and has nothing to do with changing the gears. It is there to stop a part of the hub rattling. |

|

| The back of the sprocket with painted dirt. Some cruddy bits in the hub too, but these can be cleaned away. The driver large bearing surface is in really great condition and there is a decent amount of oil evident. Note the first difference to the AW; the K has a 6 pronged driver. |

|

| View inside the hub which is a quick way to check it's condition. It seems to have rusty particles in so definitely needs cleaning out. The ball ring balls look nice and shiny though. Looking down, you can see the 6 armed clutch and the dogs on the inside of the gear ring that it engages on in 2nd and 1st gears. |

|

| The ball ring has been unscrewed from the shell, showing the internal steps that engage the high gear pawls. Those pawls are mounted in the annulus, or gear ring if you prefer the more descriptive term. You can see the pawl tails inside the gear ring. |

|

| The gear ring lifts straight off the mechanism, exposing the planet cage and six armed clutch. It's easier from this point to take the mechanism out of the shell to reach the next parts to come off and I expect that Mike will do this soon. |

|

| Ah, I was right, he did. The inside of the shell is coated with a mixture of oil and rust. This can be degreased with a solvent such as Gunk or Jizer, and clean up with hot water and detergent. You can see the pawls in the end cap on the left hand side of the hub. |

|

| Although rather cruddy, the mechanism itself is in pretty good order with thousands of miles left in it- if a gear chain can be found! The planet pinion teeth are not worn at all and the pawl steps on the right are perfect. You can see the large triangular ends of the clutch to the left of the planets. |

|

And here is a good view of the top of the clutch, showing how it is machined in the shape of triangular wedges at the end of each arm. The dogs on the planet cage are similarly wedge-shaped. Unscrew the ring nut on top of the clutch. Mike has managed to get the planet axle pins out and remove all four planets.

|

|

| This close up of the cleaned planet cage dogs shows that they are a little bit worn at the tips. Nothing serious enough to affect gear changing. The original K had a no-inbetween-gear (NIG) function but this lead to more sever wear of the dogs in question. The easiest solution was to introduce a position of no drive between gears 2 and 3, just like the later AW. The AW's planet cage dogs are formed by the end of the axles sticking out of the cage. |

|

| Here is the cleaned shell in which the pawls are easily seen. They are the low gear pawls which will drive the hub shell in 1st and 2nd gear, and are particularly robust to handle the torque. To access them for more thorough cleaning you could unscrew the left hand end cap which has a left hand thread. Note that you would need to drill out the pins if you wanted to replace the pawls or their springs. From this point of view the AW's low gear pawls were much easier to service. |

|

| The cleaned up driver. No wear evident on the driver itself but you can see that the sprocket teeth are hooked and this means it has been well used. As the sprocket is dished, it isn't really reversible and as it is a screw-on, it wouldn't be very easy to find a replacement. Possibly you could grind the sprocket from the screw thread and mig weld a new sprocket on. |

|

The cleaned-up gear ring looks very like an AW annulus. Even the pawls are the same shape, being chamfered inside. The ramps on the clutch arms help it to press the tail ends of the pawls in when low gear is selected. This stops the pawls engaging the shell, and so drive goes instead through the low gear pawls on the left of the hub.

|

|

|

Here is view of the cleaned gear ring or annulus. Note that at the same time the clutch would be tripping the pawls in 1st gear, it also engages the dogs on the gear ring to drive it. If you look closely, you can see wear on the dogs at the top, clear of the pawls. This is where they would have been driving the hub in second gear, the pawls not tripped. In the original K, those dogs would be longer and not bear such high pressure from the clutch.

|

|

| This view is of the main spring inside the axle. Mike and I had much puzzlement working out how this spring was retained in the axle. The disassembly instructions refer to a grub screw in the end of the axle. We found it in the end, a screw with a hole in the centre, so more like a short tube. |

|

| This is perhaps the most deteriorated part on the hub. The grease used must have been insufficiently repellent to water. The balls can be replaced, probably 1/4" diameter like later AW balls. The cone might be improved with fine emery paper. If the cone was spun with a battery drill, the paper would polish up the surface ok. |

|

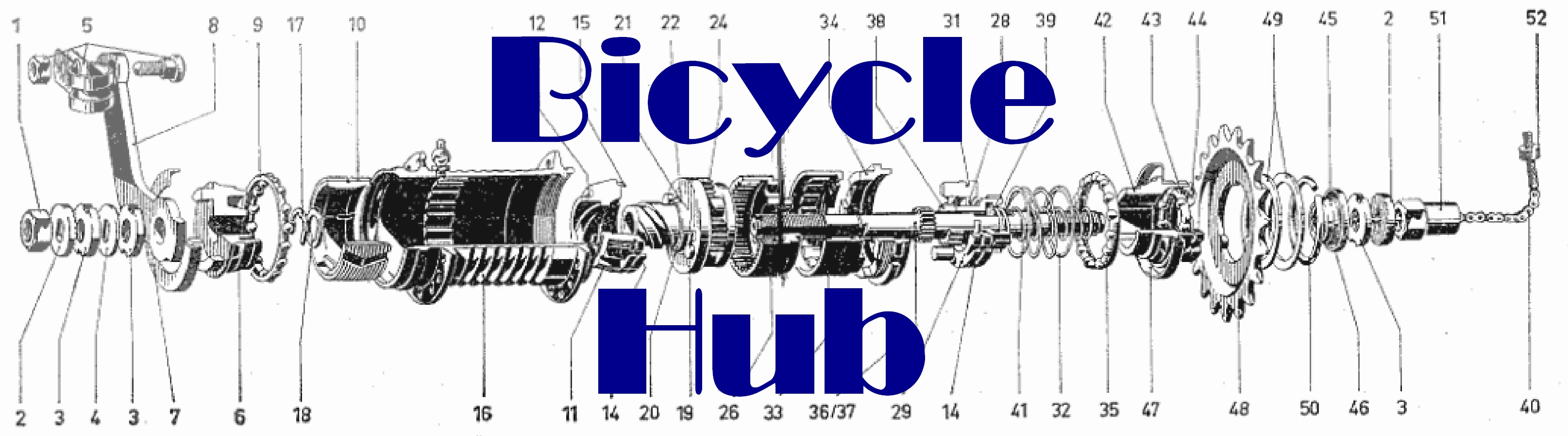

| Here are all the parts laid out systematically in order, and quite artistically too. The large spring is in the wrong place- tsk tsk! Mike has obviously confused the hub with an AW and thinks it is a clutch spring. |

|

|

On the home straight now.All parts of the epicyclic mechanism are in their completed sub-assemblies. The end of one of the planet pins looks mis-shapen. Dodgy quality. But just remember that they were banging them out by the thousand.

|

|

| Spurred on by the missing toggle chain Mike had an idea to replace the unthreaded axle key (left) with an AW threaded key (right). A spoke may then be screwed into this (it's the same thread) to pull it and change the gears. This will mean that the hold off spring won't be employed, but the AW doesn't have one either. |

|

Here is the planet cage installed on the axle with the planet pinions meshing with the sun gear. The axle key collar has also been slid into position on the axle.and the key fitted. There will be nothing physical to keep it from rotating so Mike screwed in a spoke from the left hand side.

|

|

| The clutch has now been added and the screw-on collar that holds it. In an AW, the collar is a loose fit and a spring holds it in position which is a great simplification. It means that the spring in the axle is not necessary either. |

|

| The gear ring is placed over the planet cage meshing with the planets. You may put the axle upright in the vice if you like to make it slightly easier. Not the little R spring clips on the pawl pins to stop them coming out which is quite a nice feature that was deleted on the AW. Every little time saving makes a big difference if your factory makes a million hubs in a year. |

|

| The mechanism is now installed in the shell. Note the spoke to hold the axle key hole in the right orientation. All that remains is to screw on the ball ring. This was a bit tough to screw in by hand. It needed a tool like a vice on the ring and a wheel rim held to the hub by a few spokes. |

|

|

The job was completed next day. Nice work!

K5 means that the hub was made in 1935. When the AW was introduced later in the 1930s it was given the code A8 or A9. After the war, Sturmey-Archer standardised everything by giving all hubs a model name and a separate year.

|

|

The first world war gave Sturmey-Archer's designers time to rationalise and improve their type A 3 speed hub. The type A was not related to the later series A hubs that included the AW, AM and ASC. It was simply a stopgap until the K had been tested and was ready to launch in 1921. An early niggle was the rattling planet cage, so a spring was fitted to shut it up. The type K differed from the type X still being made by BSA in that it only had a sliding clutch. This was a forerunner of the system that was later used in many other Sturmey hubs, notably the AW. The type X has most of the mechanism sliding along the axle to change gears. Unfavourable comparisons were made with the BSA hub and Sturmey-Archer very nearly went back to the type X more than once. Instead they spent money improving the finish of the K and advertising it heavily, which in hindsight was probably a good decision as it paved the way for the AW.

The first world war gave Sturmey-Archer's designers time to rationalise and improve their type A 3 speed hub. The type A was not related to the later series A hubs that included the AW, AM and ASC. It was simply a stopgap until the K had been tested and was ready to launch in 1921. An early niggle was the rattling planet cage, so a spring was fitted to shut it up. The type K differed from the type X still being made by BSA in that it only had a sliding clutch. This was a forerunner of the system that was later used in many other Sturmey hubs, notably the AW. The type X has most of the mechanism sliding along the axle to change gears. Unfavourable comparisons were made with the BSA hub and Sturmey-Archer very nearly went back to the type X more than once. Instead they spent money improving the finish of the K and advertising it heavily, which in hindsight was probably a good decision as it paved the way for the AW.  The type K stripdown follows. Note that the indicator rod and hold off spring for the hub were missing which made the hub cheaper on ebaY, if useless. I have a Type KB which has an integral hub gear and drum brake the same size as a Dynohub. This possessed the spring, indicator rod and toggle chain and they are shown on the right.

The type K stripdown follows. Note that the indicator rod and hold off spring for the hub were missing which made the hub cheaper on ebaY, if useless. I have a Type KB which has an integral hub gear and drum brake the same size as a Dynohub. This possessed the spring, indicator rod and toggle chain and they are shown on the right.