Moulton Mk3 Sealed Bottom Bracket

How to put an off-the-shelf cartridge into a Raleigh frame.

There are two assemblies on old Moultons that are difficult to refurbish. The first are the steering bearings; the second is the bottom bracket assembly. If you want to keep your original Nicklin chainset with the delicate pentagram design and polo-mint chainguard, you may be in for a tussle with a three piece, loose balls, cottered bottom bracket. This is the usual scenario: You take out the old cups, bearing balls and spindle of the cottered bottom bracket. You clean everything up meticulously and discard the old balls. The surfaces may look slightly worn, but there is no damage, galling of the bearing surfaces. "I'm on the home straight now" you think. But no matter how carefully you adjust the left hand cup, the spindle revolves with a rumbling feeling. At one angle, it is cringe-makingly tight, at another angle it is too loose and rocking can be felt. At one time I would have thought "Oh well, it will wear in" and just accepted a compromise. My legs are tolerant of a rumbling bottom bracket.

The problem with the English bottom bracket design is that it is all in separate parts. If the clearances are a few hundredths of a millimeter too loose, you can feel the play. Vice-versa, a few hundredths too tight and an enormous load presses onto the bearing surfaces. No wonder the sealed cartridge has been so successful. Industrial quality bearings all perfectly ready-aligned, correctly adjusted and silky smooth. They seem to last for ever and you can feel the difference an upgrade makes. St. John Street Cycles now offer a sealed cottered bottom bracket. Hooray! This is a direct replacement in a Series 1 or 2 Moulton and the original chainset can be refitted.

Supposing you favour an upgrade to a cotterless aluminium alloy chainset and desire long-lasting smooth rotation? A sealed cartridge is definitely the boy for you as it almost always comes with a square tapered axle.

Problems with Raleigh bottom brackets

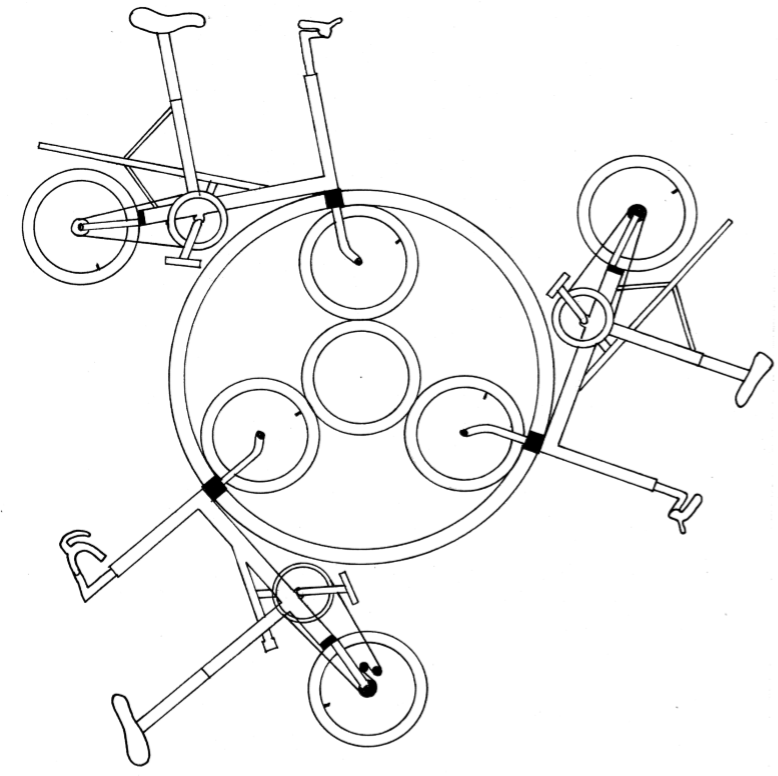

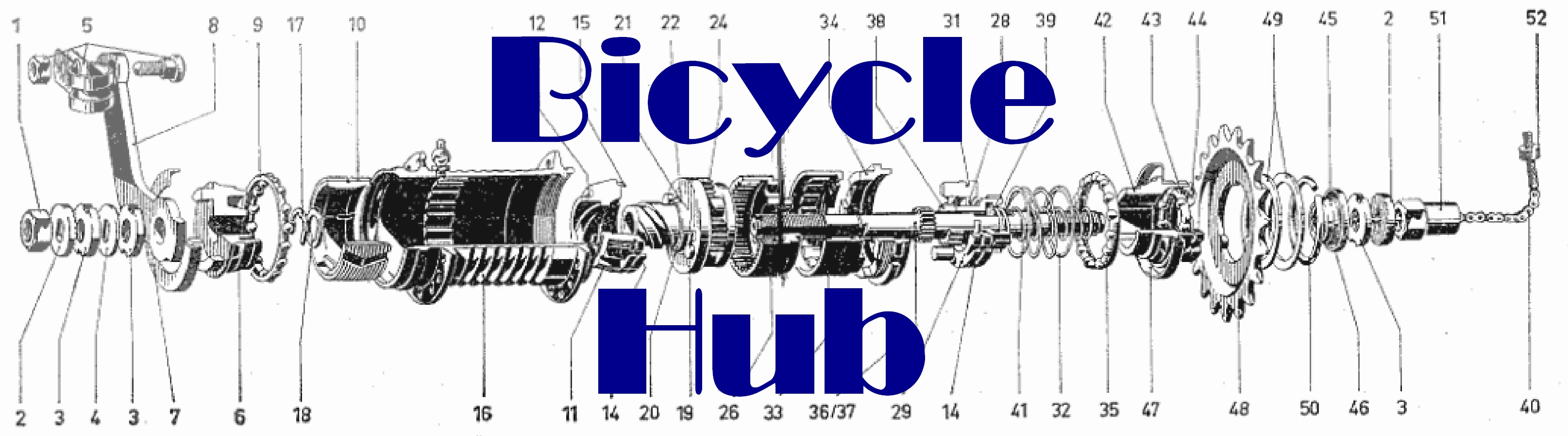

Click on the first photo to start the gallery.

So, you're convinced. It's a new cartridge for your Raleigh-built Mk3. The difficulty is that Raleigh made things to their in-house specifications. Before I knew about this, I forced ordinary bottom bracket cups into Raleigh frames wondering why the hell was so difficult. Ordinary BSA cycle thread cups have 24 teeth per inch. Raleigh used a finer 26 teeth per inch. This means that you cannot go to the bike shop and ask for a Raleigh-threaded sealed cartridge, because nobody in the UK (as far as I am aware) makes them. Sheldon Brown's page tells you all about it. He also has some suggestions for upgrades. An American company, Phil Wood, makes "Corsa" cups to fit Raleigh-threaded bikes and a sealed cartridge to go with them. The quality looks brilliant but it is relatively expensive, including the tool and seals around £200, plus postage from the USA.

Even if you could get around the thread problem, there is another difficulty. From the sixties to the eighties, Raleigh made wider bottom brackets than everybody else. The Moulton Mk3 has one of these, and it measures around 75mm instead of the usual 68mm. Clearly, even if you are sticking with a cottered chainset, it is not a straightforward matter to get hold of a new spindle the correct length. Somehow, I don't see it being on the shelf at Halfdros. And anyway, it is usually worn cups that are the main culprit(s). Although the cottered bottom bracket from SJS is sufficiently long enough for the Mk3, the English threads are wrong. You can buy threadless cartridge bottom brackets quite easily and SJS do those too. But not to fit bottom brackets as wide as Raleighs. Could the Raleigh bottom bracket tube on the bike be faced down to 68mm? No, because it has flanges on each end which the rear forks are hinged from. Enough preamble. It all adds up to a significant headache for the seventies inclined Moultoneer.

Is there an alternative?

Arthur Smith of Moulton Technical Support mentioned to me that he had put a cartridge into a Mk3 simply by choosing one of a certain size and removing the end cups it came with, then clamping it up *very* tight. I thought this was a great solution, but there was the obvious concern that the bracket could be displaced by an extra hard push on the pedals. And in practice I found that most cartridges were too short to be held in this way. The 'bodies' actually come in many different lengths. Nevertheless, the idea was sound in most respects; use the Raleigh cups with the sealed cartridge and prevent it from moving in the frame shell.

Even a relatively cheap sealed bottom bracket has far higher quality bearings than an original TDC or Raleigh assembly. The best kind of cartridge for this conversion is the type with acetal (Delrin is a trade name) plastic resin cups. These really seem to have gone out of favour for some reason and the Kinex cartridges that I originally recommended are no longer available. However, Thun still use Delrin cups and a good range of bottom bracket axle lengths up to 127mm. They can be bought from Tredz at this page. Shimano also make a suitable cartridge, the UN26. They are not that easy to come by but I found them on Wiggle and also Chain Reaction Cycles with axle lengths up to 122.5mm. They were in the clearance departments of both shops which might mean the UN26 is discontinued. Finally, Holland Bike Shop has quite a good selection and here is a typical unit, I think with their branding.

What you next have to determine is the optimum axle length for your chainset. This might depend upon how many chainrings you have or on the design of your chain-side crank. Some have longer projections on the inside. What I have found is that an axle length greater than 125mm is best. Note that the bracket may be adjusted from side to side to give extra clearance for the chainwheel. Another thing to remember is that although your cranks may clear the frame, you may find that they touch the back brake caliper, so be aware of this. In my experience, 125mm is usually plenty of axle length, even with the Mk3's wide bracket shell.

Modification and Installation

The first thing to do is to modify the plastic cups. The beauty of this material is that it is "squashy" and also has a certain "slipperiness" that will be useful. Take a rough file and file most, but not all, of the threads off all the way around both cups. You can leave the cup on the cartridge to make this easier. You should be able to still see the lower grooves of thread left on the cup. Next, saw the side plates off both cups using a coarse hacksaw blade. You could probably get through them with a junior hacksaw too but a vice is essential. Take care not to slip. You now have two rings, looking not unlike large black Hula Hoops.

After removing the cups from the cartridge, put the cartridge in the frame and screw on the old steel cup. Lock this in the usual position leaving the new cartridge loose. What you have to determine is the width of spacers necessary to hold the bracket in the right lateral location. By moving the cartridge to the left, measuring the axle stickout, then to the right and doing the same, you will know the the width necessary to take up with spacers. This is shown in the slideshow that follows. Also, try the chainset on the spindle to see if you want the spacers equal width or unequal. as long as the two spacers make up to the necessary total width, you can do what you like. Note that the bottom bracket shell is off-centre in design in any case.

These spacers can be made, or improvised from washers, or cut out from aluminium sheet. I am lucky enough to own a small lathe and was able to make the side spacers to exactly the correct diameter and width. But in the past I have used Moulton top bearings from the front suspension, simply because they were handy. This is really the trickiest part of the whole operation. Have a look around a hardware store to see what you can use. There may well be something in the plumbing section. What you hope to achieve is for the spacers to press on the outer shell of the cartridge, not on the bearings themselves.

The actual installation is best described by the slideshow