FM 4 Speed Medium Ratio

The Sturmey-Archer FM: F for Four, M for Medium ratio. So what would medium mean, compared to other hubs produced by Sturmey-Archer? The closest comparisons are the FW Wide ratio and the AM 3 speed Medium ratio.

| Hub Gear | FW | Typical Gears | FM | Typical Gears | AM | Typical Gears |

| First | -33.33% | 43.3" | -33.33% | 43.3" | - | - |

| Second | -21.1% | 52" | -14.3% | 55.7" | -13.46% | 56.3" |

| Third | Direct Drive | 65" | Direct Drive | 65" | Direct Drive | 65" |

| Fourth | +26.6% | 82.3" | +12.5 | 73.1" | +15.56% | 75.1" |

It is interesting to note that the ranges of the top three gears of both four speed hubs are very different, nearly 36" for the FW and only 20" for the FM. However, the ranges of the top three gears of both medium ratio hubs are very nearly the same. This shows you the benefit of the FM; it is just like the AM, but with the addition of a "crawler gear" for use on unexpected hills. The bottom gear is exactly the same ratio as the first gear of the FW. So it is almost as if you are getting the best of both worlds, a clubman's racing hub and the tourist's low ratio first whenever you need it.

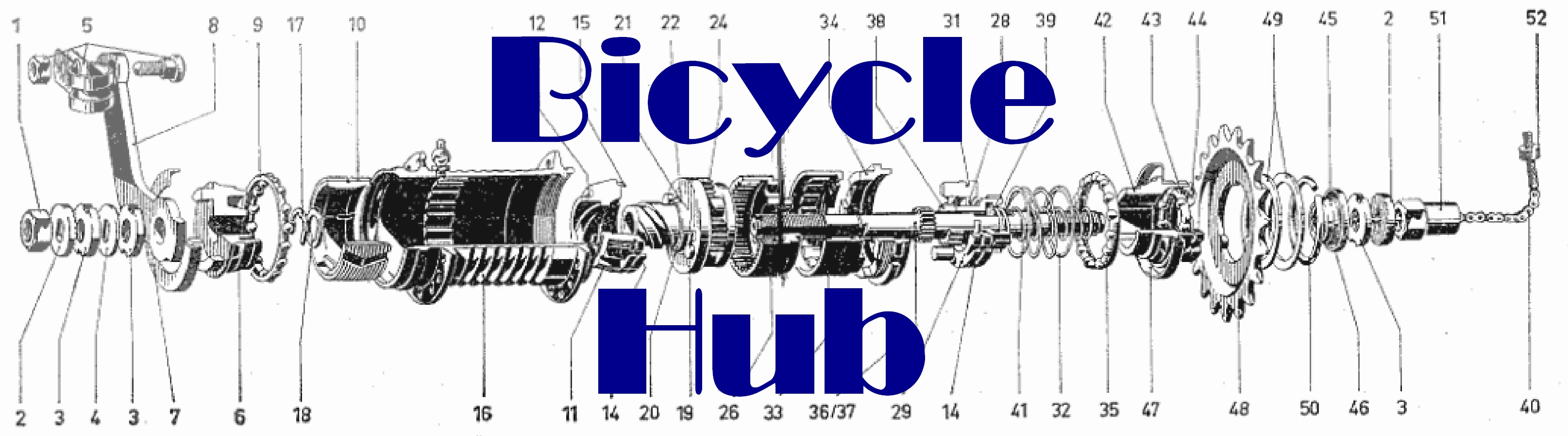

The FM achieves this using a sophisticated two stage epicyclic train in which the primary sun can be driven by the secondary planets to create a perfect gear ratio. If you have a look at the ASC hub strip and rebuild page on this website you will see that a very similar idea was put in practice to get a smaller jump from second to third than there is from first to second. This is the same in the FM, only relating to the top three gears. A racing hub ideally needs smaller intervals between the higher gears than the lower and this is a minor disadvantage of a single epicyclic design like the AM. I will show a good way to work out your optimum gear ratios on a separate page. In the meantime, let's get stuck into that FM! The hub in the stripdown was bought on ebaY for a modest sum by my brother Mike, who also carried out the work and took photos. Thanks Mike!

| Here is the FM in "as found on ebaY" state. It has an alloy shell with spoke holes that are a little raggy, but nothing to worry about. Looking at the sprocket,, the teeth look barely worn in. This could be a replacement of course. The clubmen used to change their sprockets between the training and racing seasons. Nevertheless, I think it's quite a good omen for the condition of the mechanicals. |  |

| Step 1. First the right hand cone was removed and the driver lifted off. You can see in this photo that it is being pushed up by the main clutch spring. This is because the collar on top of the spring has a wider diameter than the internal diameter of the wheelbearing race. It's no problem taking the hub apart but definitely something to watch out for in re-assembly as the collar does manage to pop through. You should always keep the collar below the bearing, usually by using the cone itself. |

|

| Step 2. Now, the driver can be lifted away which is a quick way to see inside the hub to check out it's condition. So far, it seems promising, although that oil may well have been in there since December 1954. Sturmey oil does have a very particular odour and looking at that photo, I can almost smell it. It is more usual to leave the drive side cone on and lift the whole mechanism out of the shell in one go, but it really isn't too critical what order you do the teardown operations at this stage. |

|

| Step 3. The left hand cone has been removed, and doing that before trying to unscrew the driver IS imperative. Believe me, I've accidentally tried it the other way around and been baffled why the ball ring was going tighter the more I turned. In the photo, the ball ring is gripped by the vice jaws and the shell turned anti-clockwise by the wheel rim. |

|

| Step 4. On first sight it looks like a lot more dismantling has been carried out. In fact, all that has occurred is that the ball ring has been taken off, with the annulus still under it, the clutch spring and collar and the axle key collar. The rest of the mechanism was withdrawn from the hub shell. |

|

| Step 5. Examination of the mechanism reveals that indeed, it's in very good condition! The clutch and the dogs on the planet cage are nice and square and the planet pinions have no rusting, chips or wear. The oil has dried to an almost tarry consistency. It should really be light machine oil. But this is the reason why taking old hubs apart to clean them is so rewarding. |

|

|

Step 6. Looking into the hub shell, we see it is black, but undamaged. At the far end of the hub is the left hand ball ring. This can be unscrewed if desired but it is necessary to unscrew it clockwise. The ball ring has the secondary gear train annulus machined into it, and also the steps which engage with the low gear pawls. It is not unknown for one of the ball ring steps to break off under very hard use. The steps are in perfect condition in Mike's FM. |

|

|

Step 7. There is some freewheeling wear of the face of the secondary pawl that clicks over the steps just described. The tip of the tooth at one side has some minor wear that could be oilstoned out. I don't think that either of these wear zones will be problematic. The planet pinion appears to be rusty on the closest tooth tip but as it's coated in oil and the face is not rusty, I assume that it is only congealed oil. There are puzzling vice grip marks on the planet cage that were presumably made at the factory. |

|

| Step 8. The primary planet cage has been removed and we are now looking at the driven sun. The large spring, four pronged clutch and thick plate carrying three planet pinions are all the same as the ASCs. The idea of driving the primary sun is the same too, but the sun is far larger than the ASCs. It looks as if it has at least twice the number of teeth. The entire sub assembly looks well lubricated by the age old treacle. Should clean up a treat. |

|

|

Step 9. Here are the internals after cleaning, and what a lovely job he has made of de-gunking them all. The only part left on the axle is a collar and the large sun that is locked to the axle by a nut with a washer with edges that bend over. It wasn't necessary to remove those parts to clean them. Everything is set out methodically in order which helps to create an understanding of the inter-relation of the working parts. |

|

| Step 10. Same stage, different view. Use the exploded diagram at the top of the page (it's expandable) and reverse the steps you made in the disassembly. Take care with putting the central spring in the right way round and test that the indicator rods can be screwed together when you have built up the axle assembly. |

|

|

All Finished! The FM is a nice hub to build up because although it is probably the most complex of Sturmey-Archer's classic hubs, you can make up several sub-assemblies and put them together later on. It's like a jigsaw puzzle in that respect. Sturmey-Archer won a Cyclists' Touring Club award for the FM as the greatest innovation for cyclists in 1939. |

|

|

|

Just one story before we leave this page. Many years ago Mike had an FM which was the pride of his collection. We wanted to strip it down together but didn't have the instructions. No internet in those days. So we took it all to pieces in the kitchen, much as has been done above, and cleaned it all up. During reassembly it was discovered that one of the secondary planet pinions was missing! How the hell could that have happened?  We had hardly taken our eyes off it and there were two of us watching. Darn, we'll just have to hunt until we find it. And hunt we did, everywhere we could possibly think of, over and over in the same places. In impossible places like outside in the yard. We never found that absconding pinion. No ebaY to search and get a replacement (although to be honest an old fashioned bicycle shop like Rotrax might have had one). The hubstripping adventure seemed ruined and it was a sad day. Sixteen years later when I had many more hub parts, I took the same FM apart and discovered that the small side of an FW compound planet had the same number of teeth as the missing FM planet pinion. I'd got quite a few scrap FWs so I simply ground a compound planet in half and fitted it into the depleted FM. And this is the hub used on this bike.

We had hardly taken our eyes off it and there were two of us watching. Darn, we'll just have to hunt until we find it. And hunt we did, everywhere we could possibly think of, over and over in the same places. In impossible places like outside in the yard. We never found that absconding pinion. No ebaY to search and get a replacement (although to be honest an old fashioned bicycle shop like Rotrax might have had one). The hubstripping adventure seemed ruined and it was a sad day. Sixteen years later when I had many more hub parts, I took the same FM apart and discovered that the small side of an FW compound planet had the same number of teeth as the missing FM planet pinion. I'd got quite a few scrap FWs so I simply ground a compound planet in half and fitted it into the depleted FM. And this is the hub used on this bike.